Infrastructure

Advanced Manufacturing Infrastructure for Precision and Quality

At Mikron Tools, our advanced manufacturing infrastructure ensures precision, quality control, and reliability in every product we deliver. Our facilities include a state-of-the-art tool room, production shop, press shop, quality inspection lab, and a dedicated designing section. These integrated capabilities enable us to support our clients throughout their journey—from initial design and development to manufacturing and performance optimization—delivering solutions tailored to their specific needs

Tool Room

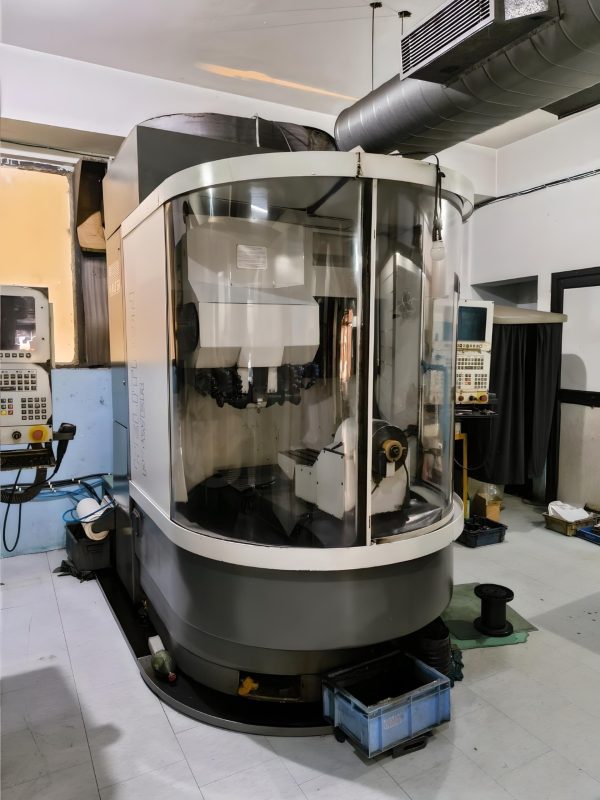

Production Shop

At our production shop, we seamlessly blend expertise with technology. Operated by skilled engineers, our facility boasts 7 CNC turning centers, 16 VMCs, and 2 CNC drill and tap centers. Equipped with advanced tooling and CAD/CAM software, we stand at the forefront of precision engineering. Our machines offer high precision, multi-axis capabilities, and high-speed machining to deliver a wide collection of features for various industries.

Press Shop

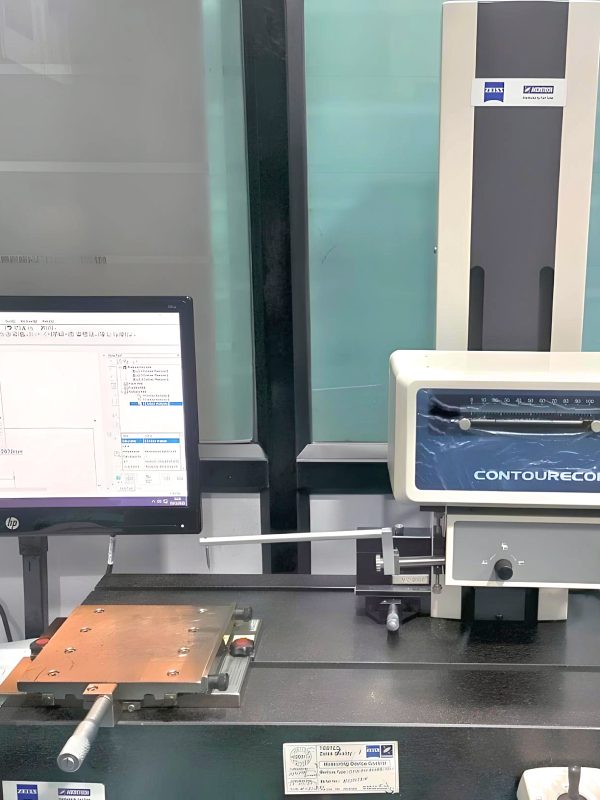

Quality Control